Projects overview

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Nulla erat nisi, tincidunt eu risus a, placerat finibus massa. Fusce viverra nibh eget dui pretium volutpat. Nullam sodales vulputate sem sed rhoncus. Nulla et feugiat velit, in faucibus diam. Curabitur tristique.

Projects

Compliance and Safety

1 May 2022

-

1 November 2022

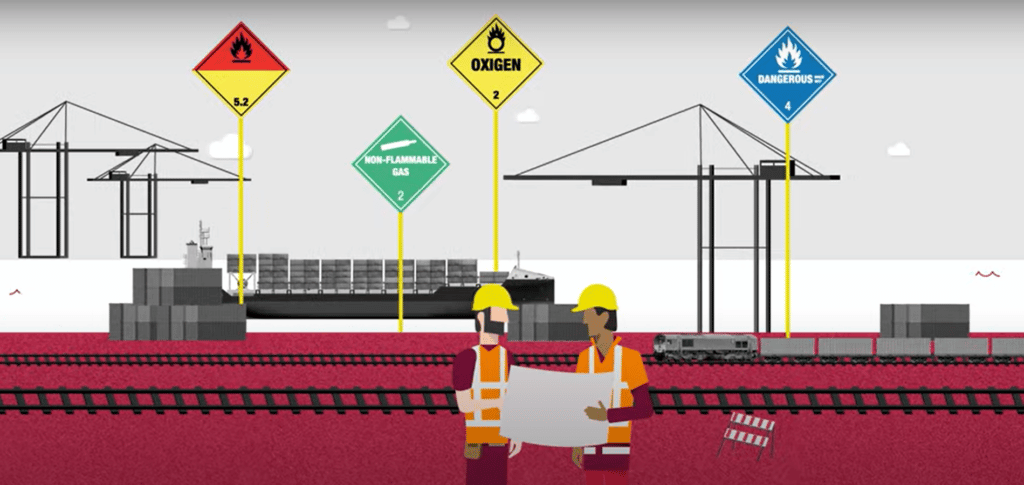

ProRail holds various environmental permits for the management and operation of the yards along the harbour rail network (Havenspoor Line). These permits outline the requirements and obligations that ProRail must meet to ensure safety on the yards (compliance and safety). In recent years, the competent authorities, such as the Rijnmond Environmental Protection Agency (DCMR) and the Rotterdam-Rijnmond Safety Region (VR-RR), have identified instances where ProRail did not fully comply with the permit requirements. Since then, ProRail has been working on various projects to enhance risk management and restore the infrastructure.

Compliance and Safety

For every violation identified by the competent authority, it shall impose a so-called ‘Last Onder Dwangsom’ (LOD) on ProRail after a warning. Such an LOD can be seen as an instrument of the competent authority to correct undesirable behavior. An LOD specifies the permit requirements that ProRail must comply with. We take effective measures to comply (again) with the specified requirements. Once we have taken the necessary measures, we are allowed to submit a request for revocation of the LOD after one year. However, in practice, it sometimes takes longer, around one and a half to two years, before the LOD is lifted. If the competent authority identifies a new violation during that period, resulting in a fine, the minimum one-year period starts again.

Stewardship

1 May 2022

-

1 November 2022

In addition to managing 7,000 kilometres of track and approximately 400 stations, ProRail also oversees dozens of yards. These yards receive many visitors, including contractors who carry out work on the premises, particularly within the context of the ‘Infrastructure in Order’ programme. Until now, ProRail did not always have a complete overview of who was present on the yards and for what purpose. Additionally, visitors were often unfamiliar with the applicable house rules. To address these issues, ProRail initiated the ‘Stewardship’ project.

In control

A rail yard is used for the positioning and shunting of trains. In the Rotterdam harbour area, the following yards are present: Waalhaven-Zuid, Pernis, Botlek, Europoort, and Maasvlakte. All these yards must comply with permit requirements established by the Safety Regions to ensure environmental safety. The competent authorities identified frequent violations, such as parked vehicles blocking emergency access roads and firefighting facilities, as well as open gates. These issues were partly due to a lack of knowledge regarding the rules of conduct among visitors and insufficient enforcement by ProRail.

So it’s time to take control and create a safe working environment for everyone at the railway yards. The most logical solution is of course to place a large fence around all yards. However, that takes a very long time, does not solve all problems and is also quite expensive. We will therefore first start with the ‘quick wins’. In the ‘Stewardship’ project, ProRail tackles about 80 percent of the problem with 20 percent of the resources and time . This approach consists of three steps:

- Making behavioural rules accessible to everyone.

- Implementing a check-in system.

- Establishing an enforcement policy.

Points Warming

1 May 2022

-

1 November 2022

Railways points are sensitive to cold and snow and can freeze or block. Winter precipitation increases the risk of points malfunctioning. As soon as it gets cold, we therefore heat a large number of the points. In the winter of 2020/2021, it turned out that more than half of the point heating on the Havenspoorlijn is not working properly. ProRail therefore replaces point heating control panels, repairs old points and deploys extra snow ploughs during winter precipitation. In this way, shunting yards, maintenance locations and freight terminals on the Havenspoorlijn remain fully available to freight transporters, even under winter conditions.

Replacement of point heating control panels

Based on the findings of the winter evaluation conducted in October 2021, it was discovered that a some of the point heating control panels were not functioning correctly. These control panels contain the technical control systems for point heating. The replacement of the first 44 control panels (including associated cables) began in 2022 and will be completed in the coming period.

In the Netherlands, approximately 5,000 out of around 7,000 railway points are equipped with point heating. In October 2021, ProRail inspected all point heating systems throughout the country.

Firefighting Facilities

1 May 2022

-

1 November 2022

The firefighting facilities at the Rotterdam harbour rail yards must be adapted by 1 January 2023. This is due to the stricter requirements of the Environmental Permit. In order to comply with the applicable regulations, the Botlek, Europoort, Maasvlakte West, Pernis, and Waalhaven Zuid marshalling yards need to have more and wider emergency roads. Additionally, the existing dry fire mains need to be replaced with wet mains. This is a task that ProRail cannot accomplish alone.

Understanding each other’s interests

The project faces several challenges. Due to time constraints, construction had to start even though the designs and contracts were not fully completed yet. We also face scarcity of construction materials and price increases, among other things. It is great to see that we are truly doing this together, with an understanding of each other’s interests.

– Sanne van den Haak, Project Manager

Infrastructure Improvement Program – the work packages

1 May 2022

-

1 November 2022

In a span of three years, ProRail is bringing the infrastructure in the Rotterdam harbour area in order. In total, we are replacing 92 points, 78 level crossings, and 20 kilometres of track on the over 40-kilometer-long freight railway line between the Kijfhoek and Maasvlakte rail yards. We have divided the work into three packages, each lasting one year.

Work distribution

In 2020, the work for the superstructure was inventoried, and the planning was made. From 2021, the work began on-site. Work Package 1 (2021) mainly focused on urgent issues that needed immediate attention: the renewal of over 50 level crossings, the replacement of 29 points, and 10 kilometres of track. The main emphasis was on the Waalhaven Zuid rail yard. For Work Package 2 (2022), we will address a total of 28 points and three level crossings, among other things. In January 2022, the contract for the third work package (to be executed in 2023) was also put to the market. In 2021, 93 percent of the planned work was completed. The remaining 7 percent of this work package will be carried out in 2022.

An up-to-date overview of the work can be found on the ProRail website.

Maasvlakte: Sand on the Tracks

1 May 2022

-

1 November 2022

The second Maasvlakte is located west of the (first) Maasvlakte. It is a new piece of land covering approximately 2,000 hectares. Due to its location, surrounded by the North Sea, elements such as wind and sand have free rein. The southwest wind often blows strongly in that area. As a result, sand from undeveloped construction sites reaches the outer edge of the Maasvlakte. Together with the Port of Authority of Rotterdam, ProRail has already implemented various measures. Meanwhile, we are also looking for more permanent solutions that will lead to a better controllable situation. To achieve this, we are collaborating with the knowledge institute Deltares, which specialises in water and subsurface research. This research has been completed, and the recommendations have been implemented.

Preventing Sand on the tracks

Mainly from the inner harbour, sand blows onto the land and rail tracks. During low tide, the sand remains uncovered, and the wind has free rein over the open Maasvlakte. The approach is twofold: on the one hand, ensuring that less sand reaches the tracks, and on the other hand, clearing the tracks of sand.

Lines of defence: natural dunes, shipping containers, and ‘big bags’

In 2020, we established two ‘defence lines’. Over a distance of seven hundred meters, 750 enormous ‘big bags’ filled with sand were placed between the container line and the track. We also found that other measures, such as applying clay and seeding the surrounding area, resulted in hardly any problems from sand in the area. Therefore, at the end of 2021, we removed the containers and placed the big bags closer to the track.

Kijfhoek

31 December 2021

-

28 January 2022

Kijfhoek is the largest rail freight yard in the Netherlands; it can be seen as a sorting centre for trains. Wagons carrying goods from various logistics centres are assembled here into trains bound for their final destinations. This is done using the ‘humping’ process, which is unique in the Netherlands.

Humping is a method of dividing up a single set of train wagons into multiple branch lines. The train wagons are pushed over a large hump (or hill). As they roll over the hump, each wagon ends up on the right track via computer-controlled points. Special ‘rail brakes’ – also automatically controlled – ensure that the wagons do not roll too fast and come to a stop at the right point.

Kijfhoek is therefore an important link between our ports and the major industrial areas in the Netherlands and Europe. Tens of thousands of freight trains depart from and pass through here every year.

Ready for 15 years

ProRail is working hard on improvements at Kijfhoek. This rail marshalling yard covers an area of 50 hectares and has 43 sorting tracks, 14 arrival tracks, and 12 storage tracks. We are addressing three important aspects:

- Modernization of the hump yard system.

- Modification and expansion of emergency roads and firefighting facilities.

- Regular replacement of tracks and sleepers.

By the end of 2026, when everything is completed, Kijfhoek will be well-prepared for the next fifteen years in terms of major maintenance.

Axle Counters

1 May 2022

-

1 November 2022

Is a section of rail track occupied or not? Currently, the Jade detection system still ‘tells’ this with track circuits. However, this system is not always resistant to sand and salt, a combination common in the Rotterdam harbour area. From the end of March 2022, ProRail will test this type of train protection on the outer edge of the Maasvlakte. The aim: a system in which the weather has less influence on train detection on the harbour railway network. If the results are good, we will replace the current system.

Robust and fewer disruptions

Parts of the Jade detection system are nearing the end of their service life. Moreover, on the outer edge of the Rotterdam harbour area, sand and salt cause a lot of disruption. We are therefore testing a new detection system with axle counters in a pilot study. The pilot will last a year, so that all seasons and weather conditions will come into play. We deliberately set up the pilot on the outer edge of the Maasvlakte to pick up a lot of valuable information. It is the first large-scale project with GAST-NL axle counters within the freight process in the Netherlands. This new detection system should be more robust and reduce disruptions.