17 april 2024

To reduce the risk of unplanned unavailability and limit ‘Life Cycle’-costs, track bars are being maintained. To prevent track bars from needing to be replaced prematurely due to damages, their condition is periodically measured using various methods.

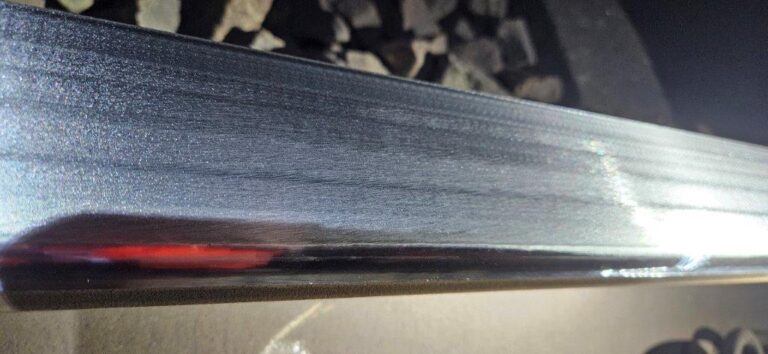

One such method is ultrasonic measurement. Based on the measurement results, milling locations are defined and scheduled. Milling a track bar can be seen as a maintenance procedure for the track bar, where between 1.0-3.6 mm of the top layer of the track bar is removed. This helps to remove small damages to prevent them from becoming deeper and ultimately detectable with ultrasonic equipment (from 5 mm depth from the top of the track bar). At this point, replacing the track bar is actually the only solution.

If damage can be detected with ultrasonic equipment, depending on the observed depth, the damage must be removed within 24 hours, 4 weeks, 3 months, or 1 year. Replacing track bars is much more expensive than milling the track bar, and it also requires many more Train Free Periods. Additionally, the risk of track bar fracture is greater with deeper defects.

In March and April, a total of five milling operations have been carried out. These will be evaluated by the end of April. In the second half of this year, a second series of milling operations will be conducted.